Ever wondered how to get more out of your business without breaking the bank? In today’s competitive market, efficiency is key.

But keeping track of inventory, managing checkouts, and ensuring accuracy can feel like a constant battle. Here’s where a surprisingly simple solution comes in: barcodes.

Think of barcodes as tiny powerhouses of information. They encode product details, streamline processes, and unlock a world of benefits for businesses of all sizes.

But the real magic lies in their return on investment (ROI).

With a minimal initial investment, barcodes can significantly boost your profits by improving efficiency, reducing errors, and ultimately, keeping your customers happy.

So, if you’re ready to unlock the full potential of your business, read on and discover how barcodes can turn a small investment into a big win.

Understanding Barcodes

Those familiar black and white stripes you see on almost everything you buy are barcodes. But they’re more than just stripes!

These seemingly simple codes are actually a complex language computers can understand.

There are two main types:

- Linear Barcodes: These are the classic barcode designs you see on most products. They encode information in a series of bars and spaces of varying widths. Common examples include UPC (Universal Product Code) used in North America and EAN (European Article Number) used in Europe.

- 2D Barcodes: These are the square or dot-shaped codes gaining popularity. They can hold much more information than linear barcodes and can even link to websites or other online content. The most common example is the QR Code (Quick Response Code) you might see on advertisements or packaging.

So, how does it work?

Each barcode symbol represents a specific character or number. By scanning the barcode, a barcode reader translates the symbols back into human-readable information.

This information can then be used to track inventory, manage sales, and access product details instantly.

Benefits of Using Barcodes in Your Business

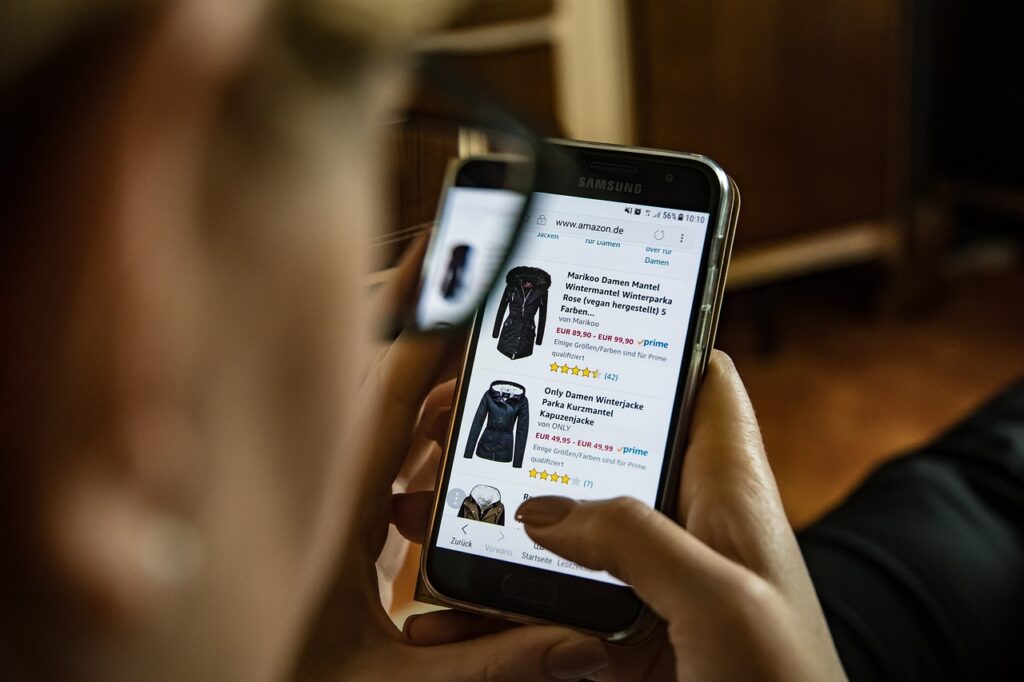

Imagine a world where inventory management is a breeze, checkouts are lightning fast, and errors are a thing of the past.

That’s the reality barcodes can create for your business.

Here’s how:

- Inventory Management on Autopilot: Struggling with stockouts or overstocked shelves? Barcodes take the guesswork out of inventory control. With a simple scan, you can track product movement in real-time, identify low stock levels before they become a problem, and optimize ordering to prevent overstocking. Cycle counts and audits become a breeze, saving you valuable time and resources.

- Efficiency Unleashed: Say goodbye to slow checkouts and manual data entry errors. Barcodes allow you to scan products at the point of sale, speeding up transactions and keeping customers happy. Order fulfillment becomes more accurate, reducing delays and frustrations. In warehouses, barcodes streamline picking and packing processes, ensuring faster order turnaround times.

- Customer Satisfaction Soars: Nobody enjoys waiting in line. Barcodes help keep checkouts moving smoothly, improving customer experience. Additionally, QR codes embedded within barcodes can provide instant access to product information or promotions, empowering your customers and adding value to their shopping experience.

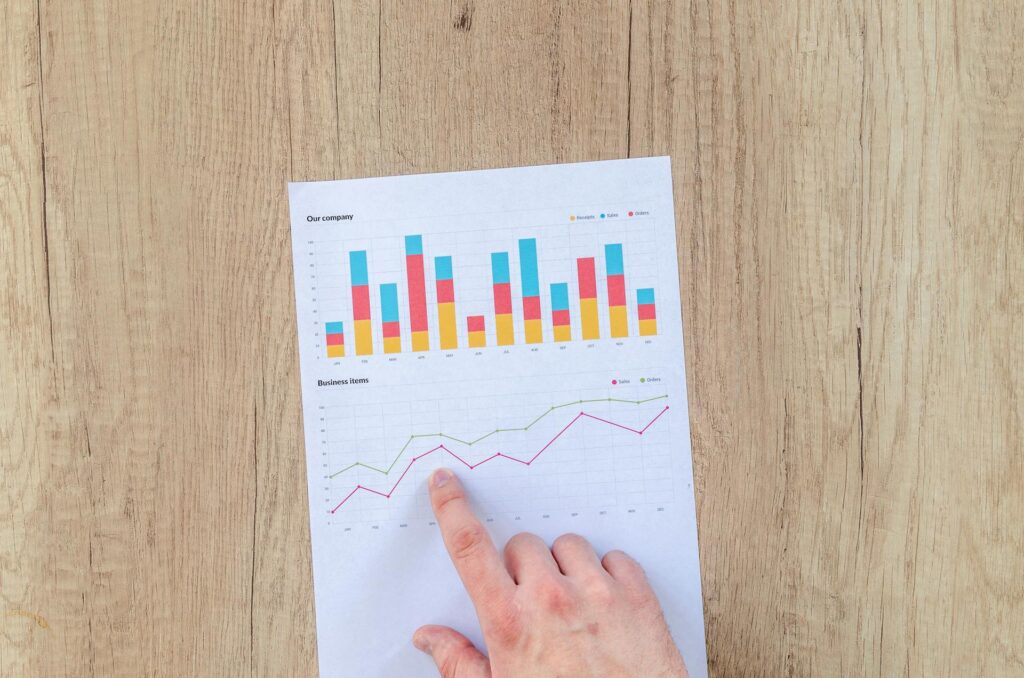

The Power of ROI: How Barcodes Pay You Back

Now that you understand the operational benefits of barcodes, let’s quantify their impact on your bottom line.

Here’s where ROI (Return on Investment) comes in. ROI helps you measure the profitability of an investment, in this case, implementing a barcode system.

Traditionally, ROI is expressed as a percentage. A positive ROI indicates that the investment generates a return greater than its cost. The higher the ROI, the more profitable the investment.

Here’s the beauty of barcodes: their ROI can be significant even with a modest initial investment. Let’s consider a scenario where you estimate to save $5,000 annually on costs by implementing a barcode system.

The cost of the system itself, including scanners, labels, and potentially barcode software, might be around $1,000.

Using the ROI formula, we can calculate that this scenario would result in an ROI of approximately 500%!

This means that for every $1 you invest in barcodes, you get $5 back in annual cost savings.

| Investment | Annual Cost Savings | ROI |

|---|---|---|

| $1,000 | $5,000 | 500% |

While the exact ROI will vary depending on your business and the specific ways you implement barcodes, this example highlights their potential to deliver a substantial return on investment.

By streamlining processes, reducing errors, and improving efficiency, barcodes can significantly contribute to your business’s profitability.

Factors Affecting ROI

Several factors can influence the ROI of your barcode system.

Here are some key considerations:

- Cost of Implementation: This includes the cost of barcode scanners, barcode labels, and any barcode software you might need.

- Labor Savings: How much time and labor will barcodes save your employees? Factor in the cost of employee time when calculating cost savings.

- Inventory Management Improvements: Reduced shrinkage, improved stock accuracy, and optimized ordering can lead to significant cost savings.

- Sales Efficiency: Faster checkouts and fewer errors can boost sales and customer satisfaction.

By carefully considering these factors, you can get a clearer picture of the potential ROI for your business.

In many cases, the cost savings and improved efficiency from barcodes can lead to a very attractive return on investment.

Getting Started with Barcodes: A Simple Guide to Big Benefits

Ready to unlock the power of barcodes in your business? Here’s a roadmap to get you started:

1. Choosing the Right Barcode:

Not all barcodes are created equal. The best choice for your business depends on your specific needs.

Here’s a breakdown of some common types:

- UPC/EAN: These are ideal for retail products and require a GS1 prefix (more on that later).

- Code 39: A versatile option for internal use, good for alphanumeric data.

- QR Codes: Perfect for linking to websites, promotions, or detailed product information.

2. Equipping Yourself:

You’ll need a barcode scanner to read the information encoded in the barcodes.

Options range from simple handheld scanners to more sophisticated options integrated with your point-of-sale system.

3. Building Your System:

- Software Integration (Optional): If you have existing inventory management software, consider barcode software that integrates seamlessly, further automating your processes.

- Labeling: Invest in high-quality barcode labels that are compatible with your chosen barcode type and printing method.

- Employee Training: Train your employees on how to use the barcode system effectively, ensuring accurate scanning and data entry.

Bonus Tip: GS1 Prefix for Retail Sales

If you plan to sell your products in major retail stores, you’ll likely need a GS1 prefix.

This unique identifier from GS1 (a global organization) allows you to generate standardized barcodes for your products, ensuring they’re recognized by retailers worldwide.

By following these simple steps, you can implement a barcode system that streamlines your operations, boosts efficiency, and ultimately, drives profits for your business.

Remember, barcodes are a powerful tool, and with the right planning and implementation, they can be a game-changer for your small business.

Conclusion: Small Investment, Big Impact

In today’s competitive business landscape, every edge counts. Barcodes offer a surprisingly simple yet powerful solution for small businesses looking to maximize efficiency and profitability.

By improving inventory management, streamlining checkouts, and enhancing customer satisfaction, barcodes can unlock a world of benefits that contribute directly to your bottom line.

The best part?

The ROI of barcodes can be substantial. With a minimal initial investment, you can reap significant cost savings through reduced labor costs, improved inventory control, and faster sales transactions.

Remember, the power lies in the data – data that barcodes capture effortlessly, allowing you to make informed decisions and optimize your operations.

So, are you ready to take your small business to the next level?

Embrace the power of barcodes.

With a little planning and implementation, you can unlock a wealth of benefits and watch your profits soar.

Don’t wait any longer – start your barcode journey today, chat with our team and experience the transformative power of this simple technology.